Introduction

You’ve probably heard the term thrown around at trade shows or in manufacturing circles. CNC machining service in the UK has become essential for businesses that need precision parts, but understanding what you’re actually paying for can be tricky. Let’s break down what matters.

What Actually Happens During CNC Machining

Computer Numerical Control – that’s what CNC stands for. A machine reads digital instructions and carves, drills, or mills material into exact specifications. No human hand touches the cutting process, which means you get the same part whether you order one or one thousand. Consistency is the whole point.

Materials They Work With

Most shops handle aluminium and steel as standard. Brass, copper, titanium, various plastics – the list goes on. Some facilities specialise in exotic materials like Inconel for aerospace applications. Ring ahead and check rather than assuming they stock what you need.

Price Isn’t Always What It Seems

That cheap quote might not include setup fees, material costs, or finishing work. Others bundle everything together. Always ask for a detailed breakdown. I’ve seen businesses get stung by “extras” that doubled the final invoice.

Tolerances Matter More Than You Think

Standard tolerance is usually ±0.1mm. Need tighter? Expect to pay more, sometimes significantly more. But here’s the thing – not every part needs aircraft-grade precision. Be honest about your actual requirements and save yourself some money.

Prototyping vs Production Runs

Making one sample part costs disproportionately more per unit than making a hundred. The machine setup time is identical whether you’re producing five widgets or five hundred. Plan your order quantities sensibly.

Quality Checks and Certifications

ISO 9001 certification means they follow quality management systems. AS9100 is for aerospace. If you’re in a regulated industry, check what certifications they hold before committing. You don’t want to discover compatibility issues after delivery.

Finding the Right Partner

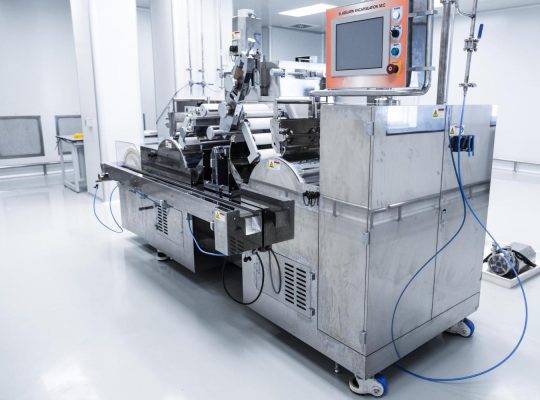

Visit the facility if possible. You learn more in ten minutes on the shop floor than from any website. Look at how organised they are, what condition the machines are in, how staff interact. These details tell you everything.

Choosing the right CNC machining service in the UK comes down to matching your specific needs with a supplier’s capabilities. Don’t just chase the lowest price – consider turnaround, quality standards, and whether they actually understand your industry. The cheapest option often costs more in the long run.